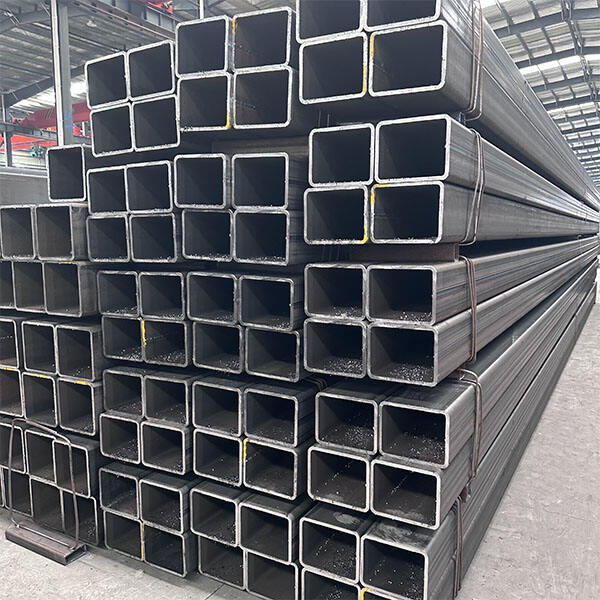

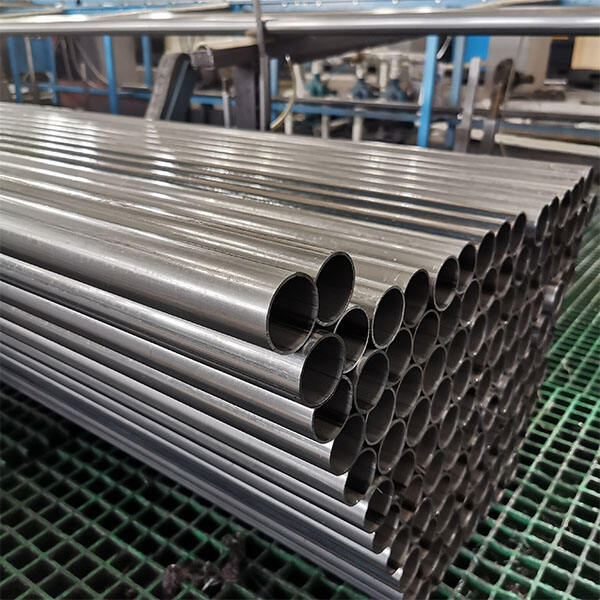

China Jiangsu stainless steel pipe manufacturers SUS304/1.4301 material seamless stainless steel pipe specifications are complete and can be polished laser punching cutting processing

- Overview

- Video

- Parameter

- Features

- Inquiry

- Related Products

We have 7 stainless steel tube production lines, stainless steel tube billet inventory of more than 20,000 tons, can achieve the customer orders on the day of production on the same day of rapid delivery of production efficiency, and our company is also equipped with stainless steel tube additional processing vacuum titanium plating, wire drawing, film, 8K mirror polishing, laser cutting, drilling and other services.

We have a professional quality inspection department, each quality inspector has more than three years of learning and training, and a production line is equipped with at least 6 quality inspectors 24 hours day and night in turn quality testing, to ensure that the product pass rate reaches 100%, for the company's products at home and abroad to create a good reputation

The company has a complete and scientific quality management system, including: CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Declaration) Environmental product declaration, French BV certification, American ABS Classification Society certification Norsk Veritas certification, environmental management system certification, ISO9001 certification, etc.

| Place of Origin: | Wuxi, China |

| Brand Name: | Jingzhan |

| Model Number: | 5mm-1500mm |

| Certification: | CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Declaration) Environmental product declaration, French BV certification, American ABS Classification Society certification Norsk Veritas certification, environmental management system certification, ISO9001 |

| Minimum Order Quantity: | The minimum order is 1 |

| Price: | 0.5$/KG |

| Packaging Details: | Packed in bundles with nylon slings 25 tons/container and 5 tons/size for a trial order; For 20" container the max length is 5.8m; For 40" container the max length is 11.8m. |

| Delivery Time: | Delivery within 7 days |

| Payment Terms: | T T |

| Supply Ability: | 10000000 Ton/Tons per Year |

Quick Detail:

Stainless steel SUS304/1.4301 Seamless stainless steel pipe is a high-quality pipe material with many advantages and a wide range of applications. First of all, it is made of SUS304/1.4301 stainless steel material, which has good corrosion resistance and oxidation resistance, and can be used in a variety of harsh environments for a long time without damage.

Secondly, the seamless process enables the pipe to have higher strength and sealing performance. Compared to welded pipes, there are no welded joints in the seamless process, thus avoiding potential problems caused by welding and providing a smoother and more uniform internal and external surface. In this way, resistance and pressure drop can be reduced when transporting liquid or gas, and leakage can be effectively prevented.

In addition, stainless steel SUS304/1.4301 seamless stainless steel pipe also has high heat resistance. It can withstand the operation of high temperature environment and maintain stable and reliable performance. Therefore, it is widely used in petrochemical, food processing, pharmaceutical manufacturing and other industries.

In addition to the above characteristics, the pipeline also has the advantages of easy cleaning, health and safety. Because its surface is smooth and easy to clean, it is ideal for use in places where hygienic conditions are required. At the same time, it is also widely used in the food and beverage industry to ensure product purity and safety when transporting liquid or powder materials.

Description:

The evolution of stainless steel SUS304/1.4301 seamless stainless steel pipes can be traced back to the early 20th century. With the acceleration of industrialization, the demand for materials with high strength and excellent corrosion resistance is increasing. In this context, people began to research and develop new stainless steel materials.

The earliest stainless steel pipes are composed of iron, carbon and chromium, but their corrosion resistance is poor. With the progress of science and technology, people have gradually realized that adding alloy elements such as nickel can improve the corrosion resistance of stainless steel pipes. Thus, in the 1920s and 1930s, a series of new stainless steel materials containing nickel elements appeared.

However, during World War II, the production and application of new stainless steel pipes were limited by factors such as resource constraints and the impact of war. Until the post-war reconstruction period, with the economic recovery and technological development once again promoted the rise of the stainless steel industry.

After the 1950s, especially since the 1960s, with the improvement of metallurgy, machining technology and equipment level, combined with advanced manufacturing processes such as cold drawing, cold rolling and other methods for production and processing improvement, stainless steel specifications have been greatly expanded and widely used in various fields.

In recent decades, with the increasing trend of global economic integration, exchanges and cooperation between different countries have increased frequently, and the demand for seamless stainless steel single-variety specifications with stable and reliable quality, excellent durability performance and meeting various environmental requirements is also growing.

Applications:

Stainless steel SUS304/1.4301 Seamless stainless steel pipe has a wide range of applications. First of all, in the construction industry, seamless stainless steel pipes of this material are widely used in indoor and outdoor decoration, handrails, stairs and so on. Its corrosion resistance allows it to remain beautiful for a long time even in Marine environments or high humidity areas.

In addition, the seamless stainless steel pipe of this material is also widely used in the food processing and pharmaceutical industries. Because of its good sanitary performance and high temperature resistance, it can ensure product safety, and it is easy to clean and maintain.

In the chemical industry, seamless stainless steel pipes of this material are also an ideal choice. Its excellent corrosion resistance makes it suitable for the transport of various chemicals and can withstand high pressure and high temperature conditions.

The automotive industry is also one of the important application areas of this material seamless stainless steel pipe. Because of its high strength, wear resistance and oxidation resistance, it can be used as an automobile exhaust system, intake system and other components.

All in all, stainless steel SUS304/1.4301 seamless stainless steel pipe with its excellent mechanical properties, excellent corrosion resistance and a variety of specifications and models, in the construction, food processing and pharmaceutical, chemical and automotive manufacturing and many other fields play an important role.

Specifications:

| Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) |

| 5 | 0.5-1.5 | 57 | 1.0-8.0 | 114 | 2.0-80.0 | 900 | 6.0-100.0 |

| 6 | 0.5-1.5 | 59 | 1.0-8.0 | 116 | 2.0-80.0 | 920 | 6.0-100.0 |

| 7 | 0.5-1.5 | 60 | 1.0-15.0 | 118 | 2.0-80.0 | 950 | 6.0-100.0 |

| 8 | 0.5-1.5 | 61 | 1.0-20.0 | 120 | 2.0-80.0 | 980 | 6.0-100.0 |

| 9 | 0.5-1.5 | 62 | 1.0-20.0 | 125 | 2.0-80.0 | 1000 | 6.0-100.0 |

| 10 | 0.5-1.5 | 63 | 1.0-20.0 | 127 | 2.0-80.0 | 1020 | 6.0-100.0 |

| 11 | 0.5-1.5 | 64 | 1.0-20.0 | 130 | 2.0-80.0 | 1220 | 6.0-100.0 |

| 12 | 0.5-1.5 | 65 | 1.0-20.0 | 133 | 2.0-80.0 | 1500 | 6.0-100.0 |

| 13 | 0.5-1.5 | 66 | 1.0-20.0 | 140 | 2.0-80.0 | 1600 | 6.0-100.0 |

| 14 | 0.5-1.5 | 67 | 1.0-20.0 | 145 | 2.0-80.0 | 1800 | 6.0-100.0 |

| 15 | 0.5-1.5 | 68 | 1.0-20.0 | 147 | 2.0-80.0 | 2000 | 6.0-100.0 |

| 16 | 0.5-1.5 | 69 | 1.0-20.0 | 150 | 2.0-80.0 | 2500 | 6.0-100.0 |

| 17 | 0.5-1.5 | 70 | 1.0-20.0 | 152 | 2.0-80.0 | 2800 | 6.0-100.0 |

| 18 | 0.5-1.5 | 71 | 1.0-30.0 | 160 | 2.0-80.0 | 3000 | 6.0-100.0 |

| 19 | 0.5-1.5 | 72 | 1.0-30.0 | 165 | 2.0-80.0 | 3600 | 6.0-100.0 |

| 20 | 0.5-1.5 | 73 | 1.0-30.0 | 168 | 2.0-80.0 | 3800 | 6.0-100.0 |

| 21 | 0.5-3.0 | 74 | 1.0-30.0 | 180 | 2.0-80.0 | 4000 | 6.0-100.0 |

| 22 | 0.5-3.0 | 75 | 1.0-30.0 | 194 | 2.0-80.0 | 4200 | 6.0-100.0 |

| 23 | 0.5-3.0 | 76 | 1.0-30.0 | 200 | 2.0-80.0 | 4500 | 6.0-100.0 |

| 24 | 0.5-3.0 | 77 | 1.0-30.0 | 203 | 2.0-80.0 | 5000 | 6.0-100.0 |

| 25 | 0.5-3.0 | 78 | 1.0-30.0 | 210 | 2.0-80.0 | ||

| 26 | 0.5-3.0 | 79 | 1.0-30.0 | 219 | 2.0-80.0 | ||

| 27 | 0.5-3.0 | 80 | 1.0-30.0 | 232 | 3.0-100.0 | ||

| 28 | 0.5-3.0 | 81 | 1.0-30.0 | 245 | 3.0-100.0 | ||

| 29 | 0.5-3.0 | 82 | 1.0-30.0 | 273 | 3.0-100.0 | ||

| 30 | 0.5-3.0 | 83 | 1.0-30.0 | 299 | 3.0-100.0 | ||

| 31 | 1.0-4.0 | 84 | 1.0-30.0 | 325 | 3.0-100.0 | ||

| 32 | 1.0-4.0 | 85 | 1.0-30.0 | 351 | 3.0-100.0 | ||

| 33 | 1.0-4.0 | 86 | 1.0-30.0 | 356 | 3.0-100.0 | ||

| 34 | 1.0-4.0 | 87 | 1.0-30.0 | 377 | 3.0-100.0 | ||

| 35 | 1.0-4.0 | 88 | 1.0-30.0 | 402 | 3.0-100.0 | ||

| 36 | 1.0-4.0 | 89 | 1.0-30.0 | 408 | 3.0-100.0 | ||

| 37 | 1.0-4.0 | 90 | 1.0-30.0 | 426 | 3.0-100.0 | ||

| 38 | 1.0-4.0 | 91 | 1.0-30.0 | 457 | 3.0-100.0 | ||

| 39 | 1.0-4.0 | 92 | 1.0-30.0 | 466 | 3.0-100.0 | ||

| 40 | 1.0-8.0 | 93 | 1.0-30.0 | 478 | 3.0-100.0 | ||

| 41 | 1.0-8.0 | 94 | 1.0-30.0 | 500 | 3.0-100.0 | ||

| 42 | 1.0-8.0 | 95 | 1.0-30.0 | 502 | 3.0-100.0 | ||

| 43 | 1.0-8.0 | 96 | 1.0-30.0 | 508 | 3.0-100.0 | ||

| 44 | 1.0-8.0 | 97 | 1.0-30.0 | 510 | 3.0-100.0 | ||

| 45 | 1.0-8.0 | 98 | 1.0-30.0 | 529 | 3.0-100.0 | ||

| 46 | 1.0-8.0 | 99 | 1.0-30.0 | 630 | 3.0-100.0 | ||

| 47 | 1.0-8.0 | 100 | 2.0-80.0 | 650 | 3.0-100.0 | ||

| 48 | 1.0-8.0 | 101 | 2.0-80.0 | 680 | 3.0-100.0 | ||

| 49 | 1.0-8.0 | 102 | 2.0-80.0 | 700 | 3.0-100.0 | ||

| 50 | 1.0-8.0 | 103 | 2.0-80.0 | 720 | 3.0-100.0 | ||

| 51 | 1.0-8.0 | 104 | 2.0-80.0 | 750 | 3.0-100.0 | ||

| 52 | 1.0-8.0 | 105 | 2.0-80.0 | 760 | 3.0-100.0 | ||

| 54 | 1.0-8.0 | 108 | 2.0-80.0 | 780 | 3.0-100.0 | ||

| 55 | 1.0-8.0 | 110 | 2.0-80.0 | 800 | 3.0-100.0 |

Competitive Advantage:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

TH

TH

TR

TR

MS

MS

BN

BN

MY

MY

KK

KK