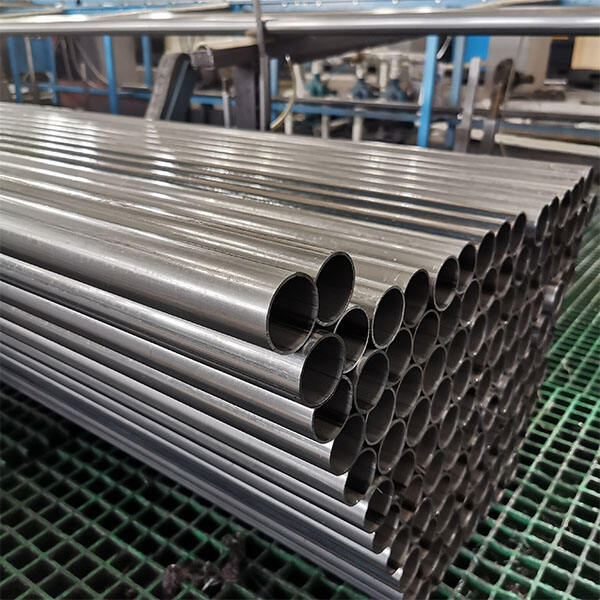

China Jiangsu production of 310S/1.4845 seamless stainless steel pipe wall thickness 1.0mm-30.0mm can be customized 310S/1.4845 material seamless stainless steel pipe can be cut and punched

- Overview

- Video

- Parameter

- Features

- Inquiry

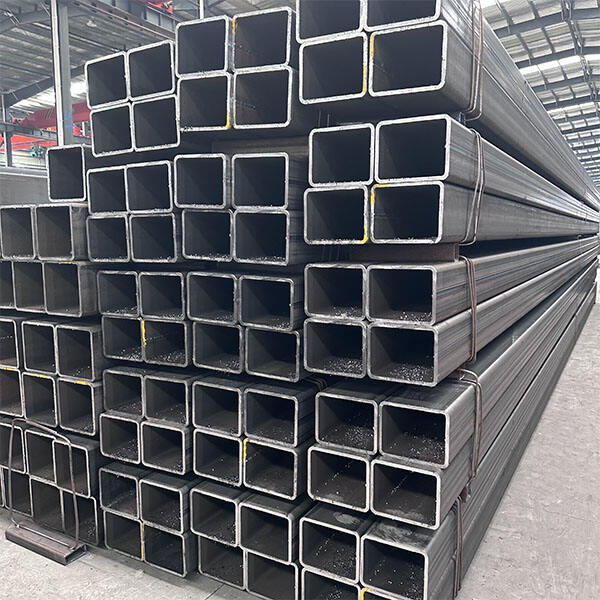

- Related Products

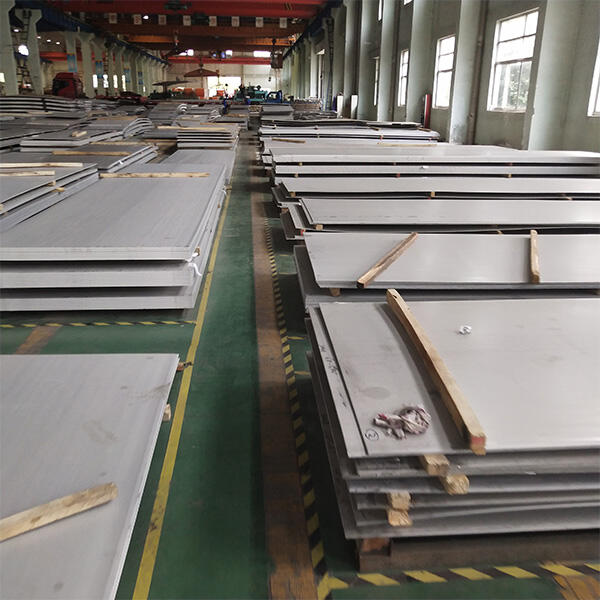

We have 7 stainless steel tube production lines, stainless steel tube billet inventory of more than 20,000 tons, can achieve the customer orders on the day of production on the same day of rapid delivery of production efficiency, and our company is also equipped with stainless steel tube additional processing vacuum titanium plating, wire drawing, film, 8K mirror polishing, laser cutting, drilling and other services.

We have a professional quality inspection department, each quality inspector has more than three years of learning and training, and a production line is equipped with at least 6 quality inspectors 24 hours day and night in turn quality testing, to ensure that the product pass rate reaches 100%, for the company's products at home and abroad to create a good reputation

The company has a complete and scientific quality management system, including: CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Declaration) Environmental product declaration, French BV certification, American ABS Classification Society certification Norsk Veritas certification, environmental management system certification, ISO9001 certification, etc.

| Place of Origin: | Wuxi, China |

| Brand Name: | Jingzhan |

| Model Number: | 5mm-1500mm |

| Certification: | CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Declaration) Environmental product declaration, French BV certification, American ABS Classification Society certification Norsk Veritas certification, environmental management system certification, ISO9001 |

| Minimum Order Quantity: | The minimum order is 1 |

| Price: | 0.5$/KG |

| Packaging Details: | Packed in bundles with nylon slings 25 tons/container and 5 tons/size for a trial order; For 20" container the max length is 5.8m; For 40" container the max length is 11.8m. |

| Delivery Time: | Delivery within 7 days |

| Payment Terms: | T T |

| Supply Ability: | 10000000 Ton/Tons per Year |

Quick Detail:

Stainless steel 310S/1.4845 material Seamless stainless steel pipe is a kind of high temperature corrosion resistant pipe material. It is made of high-quality 310S stainless steel with good heat resistance and oxidation resistance. The material performs well in high temperature environments and can withstand operating temperatures up to 1100 ° C.

This seamless stainless steel pipe has a low carbon content and a suitable ratio of chromium, nickel and other alloying elements, so that it has excellent corrosion resistance. It can resist the corrosion of acid, alkali, salt and other media on the inner wall of the pipeline, and can maintain good stability in long-term use.

In addition, stainless steel 310S/1.4845 seamless stainless steel pipe also has good processing properties and weldability. It can be formed by cold working or hot working, and is easy to connect with other metals. This provides convenience for its wide application in various fields.

This type of seamless stainless steel pipe is widely used in petrochemical, electric power, aerospace and other industries, and undertakes important tasks in high temperature environment. In oil refineries, for example, it can be used to transport high-temperature liquids or gases; In thermal power plants, it is often used as an exhaust gas emission system; In the aerospace field, it can be applied to propellant transmission systems.

In short, stainless steel 310S/1.4845 seamless stainless steel pipe with its excellent wear resistance, corrosion resistance and high temperature resistance, has been widely used in many fields, and provides a safe, reliable and cost-effective solution for related industries.

Description:

Stainless steel 310S/1.4845 Seamless stainless steel pipe development history can be traced back to the early 20th century. At that time, with the acceleration of the industrialization process and the improvement of the level of science and technology, people have higher and higher requirements for corrosion resistance, high temperature oxidation resistance and other properties. The traditional iron pipe is not ideal in these aspects.

In order to solve this problem, people began to study the use of stainless steel materials to make pipes. The earliest is the Austenitic system series (such as 304, 316), but they are easy to produce intergranular corrosion at high temperatures. Later, after incorporating a small amount of rare earth elements, a 310S/1.4845 seamless stainless steel pipe was born.

This new material has strong heat resistance and oxidation resistance and is widely used in various fields. For example, in important places such as aerospace and nuclear power plants, equipment that needs to withstand long-term operation under extreme environmental conditions uses 310S/1.4845 seamless stainless steel pipes as the main components.

With the increasing level of science and technology and process technology, there have been more types of stainless steel pipe products with better performance, and are suitable for a wider range of fields. But 310S/1.4845 is still a very important and trustworthy choice.

Applications:

Stainless steel 310S/1.4845 Seamless stainless steel pipe development history can be traced back to the early 20th century. At that time, with the acceleration of the industrialization process and the improvement of the level of science and technology, people have higher and higher requirements for corrosion resistance, high temperature oxidation resistance and other properties. The traditional iron pipe is not ideal in these aspects.

In order to solve this problem, people began to study the use of stainless steel materials to make pipes. The earliest is the Austenitic system series (such as 304, 316), but they are easy to produce intergranular corrosion at high temperatures. Later, after incorporating a small amount of rare earth elements, a 310S/1.4845 seamless stainless steel pipe was born.

This new material has strong heat resistance and oxidation resistance and is widely used in various fields. For example, in important places such as aerospace and nuclear power plants, equipment that needs to withstand long-term operation under extreme environmental conditions uses 310S/1.4845 seamless stainless steel pipes as the main components.

With the increasing level of science and technology and process technology, there have been more types of stainless steel pipe products with better performance, and are suitable for a wider range of fields. But 310S/1.4845 is still a very important and trustworthy choice.

Specifications:

| Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) | Outside diameter(mm) | thickness(mm) |

| 5 | 0.5-1.5 | 57 | 1.0-8.0 | 114 | 2.0-80.0 | 900 | 6.0-100.0 |

| 6 | 0.5-1.5 | 59 | 1.0-8.0 | 116 | 2.0-80.0 | 920 | 6.0-100.0 |

| 7 | 0.5-1.5 | 60 | 1.0-15.0 | 118 | 2.0-80.0 | 950 | 6.0-100.0 |

| 8 | 0.5-1.5 | 61 | 1.0-20.0 | 120 | 2.0-80.0 | 980 | 6.0-100.0 |

| 9 | 0.5-1.5 | 62 | 1.0-20.0 | 125 | 2.0-80.0 | 1000 | 6.0-100.0 |

| 10 | 0.5-1.5 | 63 | 1.0-20.0 | 127 | 2.0-80.0 | 1020 | 6.0-100.0 |

| 11 | 0.5-1.5 | 64 | 1.0-20.0 | 130 | 2.0-80.0 | 1220 | 6.0-100.0 |

| 12 | 0.5-1.5 | 65 | 1.0-20.0 | 133 | 2.0-80.0 | 1500 | 6.0-100.0 |

| 13 | 0.5-1.5 | 66 | 1.0-20.0 | 140 | 2.0-80.0 | 1600 | 6.0-100.0 |

| 14 | 0.5-1.5 | 67 | 1.0-20.0 | 145 | 2.0-80.0 | 1800 | 6.0-100.0 |

| 15 | 0.5-1.5 | 68 | 1.0-20.0 | 147 | 2.0-80.0 | 2000 | 6.0-100.0 |

| 16 | 0.5-1.5 | 69 | 1.0-20.0 | 150 | 2.0-80.0 | 2500 | 6.0-100.0 |

| 17 | 0.5-1.5 | 70 | 1.0-20.0 | 152 | 2.0-80.0 | 2800 | 6.0-100.0 |

| 18 | 0.5-1.5 | 71 | 1.0-30.0 | 160 | 2.0-80.0 | 3000 | 6.0-100.0 |

| 19 | 0.5-1.5 | 72 | 1.0-30.0 | 165 | 2.0-80.0 | 3600 | 6.0-100.0 |

| 20 | 0.5-1.5 | 73 | 1.0-30.0 | 168 | 2.0-80.0 | 3800 | 6.0-100.0 |

| 21 | 0.5-3.0 | 74 | 1.0-30.0 | 180 | 2.0-80.0 | 4000 | 6.0-100.0 |

| 22 | 0.5-3.0 | 75 | 1.0-30.0 | 194 | 2.0-80.0 | 4200 | 6.0-100.0 |

| 23 | 0.5-3.0 | 76 | 1.0-30.0 | 200 | 2.0-80.0 | 4500 | 6.0-100.0 |

| 24 | 0.5-3.0 | 77 | 1.0-30.0 | 203 | 2.0-80.0 | 5000 | 6.0-100.0 |

| 25 | 0.5-3.0 | 78 | 1.0-30.0 | 210 | 2.0-80.0 | ||

| 26 | 0.5-3.0 | 79 | 1.0-30.0 | 219 | 2.0-80.0 | ||

| 27 | 0.5-3.0 | 80 | 1.0-30.0 | 232 | 3.0-100.0 | ||

| 28 | 0.5-3.0 | 81 | 1.0-30.0 | 245 | 3.0-100.0 | ||

| 29 | 0.5-3.0 | 82 | 1.0-30.0 | 273 | 3.0-100.0 | ||

| 30 | 0.5-3.0 | 83 | 1.0-30.0 | 299 | 3.0-100.0 | ||

| 31 | 1.0-4.0 | 84 | 1.0-30.0 | 325 | 3.0-100.0 | ||

| 32 | 1.0-4.0 | 85 | 1.0-30.0 | 351 | 3.0-100.0 | ||

| 33 | 1.0-4.0 | 86 | 1.0-30.0 | 356 | 3.0-100.0 | ||

| 34 | 1.0-4.0 | 87 | 1.0-30.0 | 377 | 3.0-100.0 | ||

| 35 | 1.0-4.0 | 88 | 1.0-30.0 | 402 | 3.0-100.0 | ||

| 36 | 1.0-4.0 | 89 | 1.0-30.0 | 408 | 3.0-100.0 | ||

| 37 | 1.0-4.0 | 90 | 1.0-30.0 | 426 | 3.0-100.0 | ||

| 38 | 1.0-4.0 | 91 | 1.0-30.0 | 457 | 3.0-100.0 | ||

| 39 | 1.0-4.0 | 92 | 1.0-30.0 | 466 | 3.0-100.0 | ||

| 40 | 1.0-8.0 | 93 | 1.0-30.0 | 478 | 3.0-100.0 | ||

| 41 | 1.0-8.0 | 94 | 1.0-30.0 | 500 | 3.0-100.0 | ||

| 42 | 1.0-8.0 | 95 | 1.0-30.0 | 502 | 3.0-100.0 | ||

| 43 | 1.0-8.0 | 96 | 1.0-30.0 | 508 | 3.0-100.0 | ||

| 44 | 1.0-8.0 | 97 | 1.0-30.0 | 510 | 3.0-100.0 | ||

| 45 | 1.0-8.0 | 98 | 1.0-30.0 | 529 | 3.0-100.0 | ||

| 46 | 1.0-8.0 | 99 | 1.0-30.0 | 630 | 3.0-100.0 | ||

| 47 | 1.0-8.0 | 100 | 2.0-80.0 | 650 | 3.0-100.0 | ||

| 48 | 1.0-8.0 | 101 | 2.0-80.0 | 680 | 3.0-100.0 | ||

| 49 | 1.0-8.0 | 102 | 2.0-80.0 | 700 | 3.0-100.0 | ||

| 50 | 1.0-8.0 | 103 | 2.0-80.0 | 720 | 3.0-100.0 | ||

| 51 | 1.0-8.0 | 104 | 2.0-80.0 | 750 | 3.0-100.0 | ||

| 52 | 1.0-8.0 | 105 | 2.0-80.0 | 760 | 3.0-100.0 | ||

| 54 | 1.0-8.0 | 108 | 2.0-80.0 | 780 | 3.0-100.0 | ||

| 55 | 1.0-8.0 | 110 | 2.0-80.0 | 800 | 3.0-100.0 |

Competitive Advantage:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

TH

TH

TR

TR

MS

MS

BN

BN

MY

MY

KK

KK