The strong pipes have found tremendous need in the construction industry owing to incredible features. They're strong, durable and highly versatile. We will explore the top benefits of using high-quality pipes in building projects:

Unbeatable Strength and Durability: Sturdy pipes are unbendable, last long under harsh usage conditions and bear massive weight magnitudes. This characteristic ensures that buildings made from these pipes are stronger and endure for a longer time.

Rust Resistant Properties: These pipes are anti rust coated which makes them suitable to use in places where direct moisture exposure might be available like bathroom or chemicals. Also, they are able to resist corrosion from the likes of this with out deteriorating and therefore assures their long service life.

Applications of Strong pipes: The solid channels come in different shapes and sizes offering flexibility while working on development projects. This allows them to be used for a wide range of applications including supporting the structure, fencing and roofing.

Not Only This, The Low Maintenance Needs: Since steel pipes are far from getting rusty hence they require very less maintenance. If let's say an entire home is built with these types of pipes (more expensive admittedly, but the overall cost over time will be lower as repairs = repiping) it makes for no maintenance and at a low cost to whomever lives in that house.

A surge in construction projects is driving the use of robust pipes, with various key trends emerging and shaping this dynamic landscape. Recent developments with strong pipes

Growing Consumption in Developing Regions: Advancing countries are currently seeing a heightened demand for rigid pipes due to an emphasis on high-strength building materials, reflecting the need of durable construction systems in infrastructure projects.

Focus on Environmental Sustainability: As green construction practices become increasingly popular, the durability and longevity of using durable pipe materials makes them an environmentally-friendly choice.

The technological advancements are also responsible for reducing downtime and saving the cost from manufacturing to installation, which is helping all displaying availability of solid pipe materials suitable for various construction artifices.

Strong pipes are helping redefine the face of several industries, not just in construction but also due to their strength and resistance. In this next blog, we are going to dive into the many industrial uses of pipe strength - read on:

Manufacturing Sector: Strong pipes are required for manufacturing equipment and vehicles, the reason why this sector prefers mild steel as it can weather heavy machinery running inside factories.

Finally, in the oil and gas industry super pipes are very important for pipelines to resist corrosion that can jeopardize the operation of these systems.

Mining Operations: For the mining industry, durable pipes serve as structural elements for most operations or deliver materials within mines due to their strength and resistance in demanding environments.

Strong Pipes In Agriculture:-Likewise in farming, farmers are using strong pipes more and more that they have become an important part of their agribusiness because these pipes can quickly flexed wherever essential. So let us understand what are the benefits of using good pipes in farming process.

Improving Farm Safety: Steel pipes work well for building tough fences to protect livestock and crops, thus protecting them.

High Strength Pipes : Farmers use high strength pipes in irrigation setups to ensure the efficient movement of water from source through pipes into crops. These corrosion-resistant properties are essential for corrosive environments such as moisture-rich environment that decomposes other materials used for this purpose in short period.

Agricultural infrastructure: Ag buildings such as barns, storage structures and more feature high load-bearing capabilities necessary to endure adverse weather conditions or seismically-triggered physical stresses.

Powerful tubes have some wonderful features and technical specifications that lead them to the primary preference for all creation, commercial and agricultural programs. Here are the important qualities of good pipes:

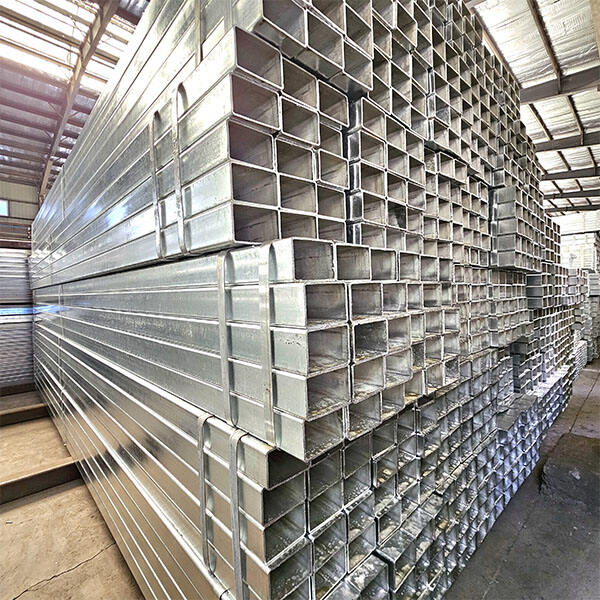

Material: These pipes are manufactured according to the standards of strong pipe and hot dip through zinc process.

Variety of sizes and shapes: Robust pipes come in a variety of size and shape ranges for different construction needs, providing customization options for numerous projects.

Non-corrosive: Non corrosiveness of Plastic Pipes makes them appropriate in the sites where they are constantly exposed to chemical, high humidity or other harsh environment.

Superior Strength-to-Weight Ratio: Strong pipes have high strength to weight ratio which makes them the ideal choice for applications that resume robustness without losing much on weight.

In summary, durable pipes prove to present a wide variety of applications in addition as well as rigid construction practices and entrenched industrial and agricultural activities. Their resistance to strength, durability and corrosion make them an attractive choice for many applications. Rising Sustainability and High Durability in Construction Materials Augment Growth for Stiff Pipes Deployment.

company operates all-encompassing and scientific quality control system, comprising: CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Declaration) Environmental product declaration, French BV certification, S355JR Hot-dip galvanized rectangular pipe ABS Classification Society certification Norsk Veritas certification Environmental Management System certification, ISO9001 certification, etc.

also provide hot-dip-galvanizing, we have our hot-dip galvanizing plant. permits to create S355JR Hot-dip galvanized rectangular pipe have high zinc layer. We are able to spray, sandblast and paint the products.

own our own manufacturing line, using raw materials our product keep inventory that S355JR Hot-dip galvanized rectangular pipe100,000 tons have all sorts of inventory of materials, have their own laser machine, can cut, punch, welding processing.

are a highly skilled inspection department. Each quality inspector goes through average of three years of training is constantly learning. production line staffed with least six quality inspectors rotate quality testing 24 hours a day, S355JR Hot-dip galvanized rectangular pipe night, to make sure that the passing rate of products reaches 100%. can help company establish a reputation at home as well as abroad.

Copyright © JingZhan Metal Technology (Wuxi) Co., Ltd. Alle rechten voorbehouden. Privacybeleid