The mystery behind Titanium plated stainless steel plates is solved

The titanium plating is a chemical process which allows to combine the most appreciated characteristics of both materials in order that stainless steels start to be strong and, at once, more colorful. This ofcourse makes the steel last longer and stay looking good. This is a process used by manufacturers in different industries and it allows them to make their products better.

All along, this has been made even better by forming it around a center of titanium -- which is extremely strong and light. It has good chemical resistance, but can be machined with a stainless steel and combines the tough surface properties typical of titanium wrought materials after it being cold rolled. With titanium plating, stainless steel plates can be colorized which provides more options for designers.

This alloy material can make plates more durable and less prone to breakage because the titanium is added into stainless steel plate. What these all mean is that plates made with these products last long and do not need to be replaced in near future. This makes plates look nicer as well, so its a good solution for selling more software products.

Those plates are a popular item in various industries such as furniture production, home appliances and manufacturing-related Industries like aerospace or automotive. They are also used in the medical field to create surgical implants, for being both durable and biocompatible. They are also used by Telcommunications companies since they can go outdoors for a long time.

The method used to perform titanium plating is known as Physical Vapor Deposition (PVD). This controls the amount of titanium coating in addition to how it appears over stainless steel. This results in a stronger, tougher steel.

have a highly skilled quality inspection department. Each Titanium plated stainless steel plate inspector has least three years of experience and training. production line outfitted with at minimum six quality inspectors 24 hours day night for quality testing to ensure that the quality has 100% pass rate and our products home and abroad establish a positive reputation.

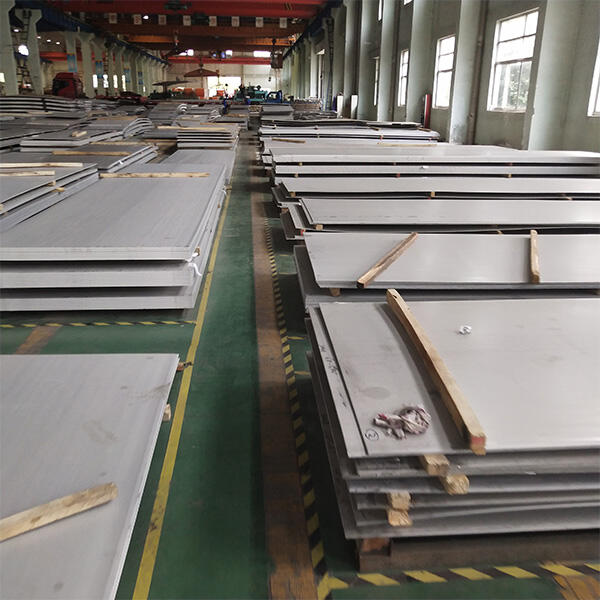

We own our own manufacturing line. Our inventory is greater than 100,000 {{keywords}} of raw material. We also have a laser that is used to cut, punch or weld.

company's quality management system complete and scientific, accompanied certifications CE certifications, Japanese JIS certificates, EN10219 certifications, EN10210 certifications, EPDs (Environmental Product Declarations) Environmental Product Declarations, French BV Certifications American ABS Classification Society Certifications Norsk Veritas, certificates for system environmental Titanium plated stainless steel plate, ISO9001 certifications, etc.

also provide hot-dip-galvanizing, we have our hot-dip galvanizing plant. permits to create Titanium plated stainless steel plate have high zinc layer. We are able to spray, sandblast and paint the products.

Copyright © JingZhan Metal Technology (Wuxi) Co., Ltd. All Rights Reserved Privacy Policy