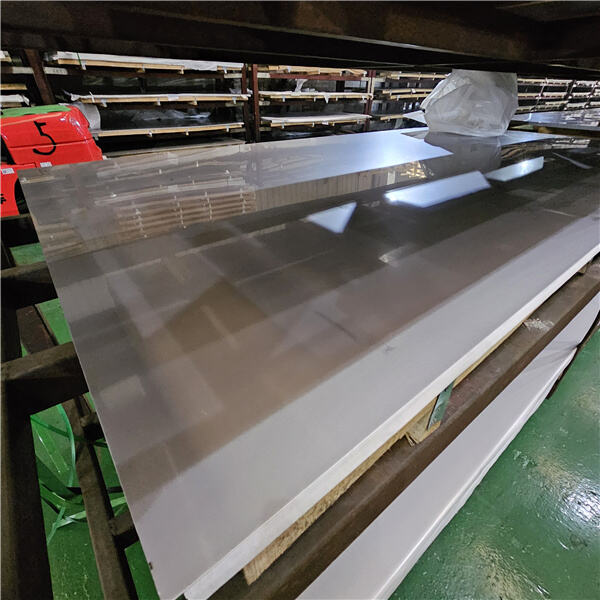

Stainless steel is one of the strongest metals in existence and it also has a reputation for lasting quite a long time. JINGZHAN 201 ανοξείδωτη πλάκα is frequently used in the making of things that must be strong and enduring like items. Stainless steel can also be formed into large, flat pieces known as stainless plate sheets. In this article, we will look at various features of stainless plate sheets. From the application of these sheets, in multiple jobs and industries to their benefits, from variety of materials used for construction thereof even the right maintenance techniques as well as choose thickness and size depending upon requirements.

There are a lot of great advantages to using these stainless plate sheets and I wanted to take them off your shoulders. One of the key aspects is that they are very durable materials, and do not rust or degrade easily so can last a long time without failing at all. This rust resistance is further important for things that are directly exposed to moisture or live in harsh environments. Moreover, stainless plate sheets are easy to clean. That is great for kitchens and anywhere you need to keep things sterile. Its immense strength and durability make them ideal for a very long list of product applications, from household goods to industrial instruments up to the construction of entire buildings.

They are employed in numerous global industries because of the tough and robust nature. In the construction sector, for example: builders need these sheets to help build robust structures such as bridges and buildings which have a considerable weight of floor. metamodels. Another important application in the aerospace industry stainless plate sheets are necessary for creating parts of airplanes and rockets, which need to be both light-weighted and strong at the same time. Based on the in food and beverage industry, stainless plate sheets are highly demanded. JINGZHAN Πλάκα καθρέφτη από ανοξείδωτο χάλυβα are commonly used in the manufacture of consumer products such as kitchen equipment, hand basins and their packaging to preserve food or drink untouched.

The steel which makes up stainless plate sheets is composed of a mixture of certain metals, like chromium and nickel as well some carbon. Because each one of those metals does something different in your body. For example, chromium is the element that provides stainless steel with its key resistance to rust and corrosion. Nickel this is what provides the steel, strength so JINGZHAN Πλάκα από ανοξείδωτο χάλυβα 310S can last longer. The carbon is responsible for providing the stainless steel that hard and toughness to whist and pressure or impact. Another attribute of stainless plate sheets is that they will work well under varying temperatures, which means if you need to use them in high heat environments, these are going to be perfect and not become damaged.

Let us help you protect your Stainless Plate from the start with various methods to maintain and extend its life. A standard method of which is passivation. In doing so, impurities in the stainless steel are removed from its surface to promote corrosion resistance. One other possible 321 ανοξείδωτη πλάκα is electropolishing. This is just passing an electric current to stainless steel, which it gives a bright and clean surface. This is a crucial facet, especially in active food and beverage sectors where hygiene and sanitation are higher concerns.

There are numbers of important factors that should be considered while selecting the thickness and size of stainless plates sheets for your project. In any case, thicker sheets are also heavier and more robust, so more applicative to heavy-duty applications. Yet, they can additionally be bulkier and extra expensive. Thinner sheets on the one hand will save you some schnitzel, or be generally more lightweight- but they might not cut-the-mustard when it comes to strength. 430 ανοξείδωτη πλάκα is also important to choose the appropriate size according to your design. Picking the right size can go a long way in how well and practical your end product will come out.

have a highly skilled quality inspection department. Each Stainless plate sheet inspector has least three years of experience and training. production line outfitted with at minimum six quality inspectors 24 hours day night for quality testing to ensure that the quality has 100% pass rate and our products home and abroad establish a positive reputation.

also provide hot-dip-galvanizing we also have our own hot-dip Stainless plate sheet plant. This permits us create products with a high zinc-layer. are equipped spray, sandblast paint items.

have own manufacturing line. Stainless plate sheet more than 100,000 tons of raw materials. also have a laser which is able to cut, punch or weld.

quality management system comprehensive and scientific. includes Stainless plate sheet such as: CE certifications, Japanese JIS certificates, EN10219 certifications, EN10210 certifications, EPDs (Environmental Product Declarations) Environmental Product Declarations French BV Certifications American ABS Classification Society Certifications Norsk Veritas, certificates the system environmental management, ISO9001 certifications, etc.

Πνευματικά δικαιώματα © JingZhan Metal Technology (Wuxi) Co., Ltd. Με την επιφύλαξη παντός δικαιώματος Πολιτική Προσωπικών Δεδομένων