There are few types of square pipes than hot-dip galvanized, largely because they hold the answer to that relentless problem when considering ferrous materials - rust and corrosion. It involves joining a layer of melted zinc over the steel to create an inert bond that is both fiercely strong and profoundly tough, able to resist even quite possibly harmful environmental conditions. In this further discussion, we will explore more reasons why hot-dip galvanized square steel pipes still dominate the market for construction projects. In this guide, we cover some of the advantages to plastic-coated steel cables and explain how galvanization ensures lingering durability that makes it great for outdoor applications.

Thus, one of the most marked benefits from using hot-dip galvanized square pipes is its unequaled long-lasting. These pipes are protected against the elements of water, wind and dust, all of which contribute to rusting / corrosion in other metallic structures over time using a process called galvanization. Galvanized steel is simply that, raw steel covered with a protective coating of zinc to prevent the pipe from rusting as it is exposed to your normal basement moisture. Moreover, the installation and maintenance of hot-dip galvanized square pipe are much easy if we compare with any other types of pipes from its features that have made them ideal choice for some great infrastructure projects like bridges, buildings such as highways and so on.

The hot-dip galvanization process is the most popular method of applying a metallic basic coat on steel components. The process involves passing steel pipes through a molten bath of zinc at temperatures around 860 °F. The layer applied merges the hot-dip galvanized (HDG) layers or in this case with the mild ASTM A500 Grade B Welded rectangular tubing creating one single solid corrosion resistant structure, which comprises both the bolt and nut products used to connect parts together! In addition, hot-dip galvanization provides an even coating across the surface of the pipes that prevents any balks or creases allowing moisture to accumulate. This ensures environmental sustainability as even the zinc coating that is used for such purpose can also be reused.

Having been processed via hot-dip galvanization, square pipe manufacturers develop with the characteristics of durability and resilience to extreme weather including very heavy rains, snow falls or high temperatures in construction work outdoors. As a result, builders largely tend to use them in outdoor building projects including bridges, pedestrian walkways and highways as well as transmission towers for power lines. Additionally, these pipes are incredibly long-lasting-delivering high-performance for up to 50 years in some of the most corrosive conditions. Their light weight and ease of installation also make them very well suited to buildings that need quick erection.

Hot dip galvanizing is a go-to method for preventing corrosion and derives its reputation based on effectiveness, longevity of protection as well as speed at delivery all along with affordability. Painting, epoxy coating and powder coating exist as alternative options widely used between here. Painting and epoxy coating are relatively less expensive than galvanization technique but do not compensate for the same level of efficiency within a fraction, on top of which they need consistent maintenance to retain their abilities. This makes the process a little more time-consuming in contrast to galvanization despite powder coating being advertised as more expensive than full-on hot-dipping.

All-in-all, hot-dip galvanized square pipes turn out to be the best solution for rust and corrosion problems of metal constructions. It guarantees that pipes can effectively resist against the external agents, thereby increasing the lifespan of buildings. Do not underestimate the significance of using hot-dip galvanized square pipes in outdoor constructions. Apart from being more affordable and effective than traditional methods of corrosion prevention such as painting, powder coating or epoxy coating they allow building contractors to save a substantial amount of money when constructing resilient and long-lasting structure.

are a reputable inspection department. Each Hot-dip galvanized square pipe inspector receives more than three years training learning. A production line is staffed with at minimum six quality inspectors perform quality tests 24 hours day, each night, to make sure that the passing rate of product reaches 100 percent. This helps the company to build a solid reputation in the United States and around the world.

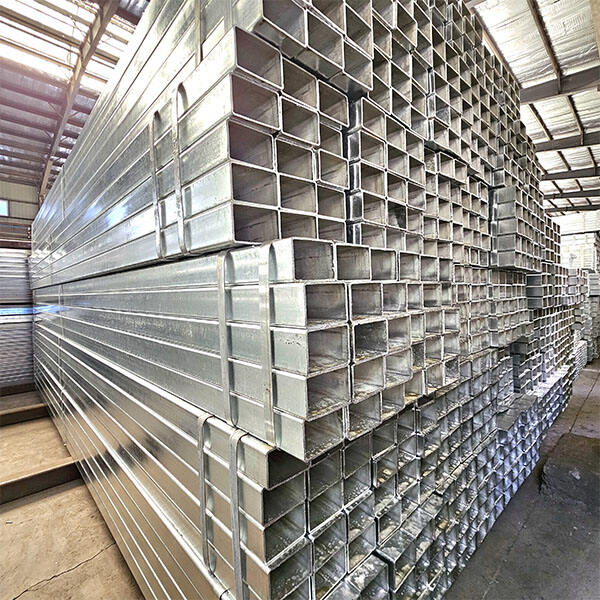

own our own manufacturing line, using raw materials our product keep inventory that Hot-dip galvanized square pipe100,000 tons have all sorts of inventory of materials, have their own laser machine, can cut, punch, welding processing.

company has completed scientific quality control system, including CE certification, Japanese JIS certification, EN10219 certification EN10210 certification, EPD (Environmental Product Hot-dip galvanized square pipe) Environmental declaration products, French BV certification, American ABS Classification Society certification Norsk Veritas certification of the environmental management system, ISO9001 certification, etc.

also do hot-dip galvanizing processes, own our hot-dip galvanizing plant which create high zinc layer galvanized goods, we can spray, sandblast paint, paint, any other surface treatment of products. can provide customers with cutting and welding Hot-dip galvanized square pipe-stop service, eliminating need for third-party processing caused by transport costs.

Copyright © JingZhan Metal Technology (Wuxi) Co., Ltd. All Rights Reserved Privacy Policy