The 310S stainless steel plates are also used in the industrial sector and is a high valuable product due to its incredible properties. These fact plates are highly strong, unified material taking out the threat of low alkaloids and corrosion. 310S stainless steel plates are widely used in the market due to their excellent characteristics among various types of stainless steels. We will delve into why they are so popular later.

Specialists use 310S stainless steel plates with wide applications in environments in which temperatures get pretty high. They are widely used in industrial applications, including ovens and heat exchangers where hot temperatures can reach 1100 deg C remarkable resistance to oxidation whilst retaining mechanical properties at high-temperatures.

Furthermore, aside from its high-temperature tolerance, 310S stainless steel slabs demonstrate greater good ductility and ruggedness. These properties are vital to allow the material to survive at these high temperatures without cracking or breaking.

There are many factors that you need to keep in mind while finding a supplier of 310S Stainless Steel Plates. To start, choose a supplier that provides an array of customization options - especially if you need plates in non-standard sizes, thicknesses or configurations. Second, select vendors that have a strong track record for providing high-quality and reliable goods. Finally, as a cost-effective way of keeping production costs down you should seek after suppliers who offer competitive pricing.(Translated from source)

310S stainless steel plates are not only incredibly flexible but also thrive in virtually any environment. This kind of adaptability makes them perfect for industries such as chemical processing and aerospace manufacturing. Equipment constructed to store and transport a variety of hazardous materials is made with stainless steel plates used in chemical processing. Both 310S stainless steel andplates are designed to be utilized in suchare suited for use in these services because of their high heat as wellcorrosion resistance requirements. Just as importantly, stainless steel plates are used to create aircraft engines and heat shields in the aerospace industry due to their high-temperature resistance properties and corrosion-resistant capabilities.

Combatting Oxidation and Corrosion with 310S Stainless Steel Plate True longevity of these sheets comes from the resistance to both oxidation and corrosion.

One of the key features that separates these products from alternatives is their excellent corrosion resistance. The surface of these plates is covered with an oxide layer, which helps to protect the metal. The strength and anti-corrosion properties are due mainly to the high levels of chromium and nickel contained in 304 steel. Most of the time this layer keeps oxygen and other harmful substances away from the metal they protect. This makes 310S stainless steel plates perfect for use in severe environments where corrosion is an issue.

To sum up, the adantages for 310S stainless steel plates to be used as a super material on wide condition with it high-tenacity,corrosion-resistant and heatproof. If you work in the chemical processing, aerospace or any other type of industrial sector where 310S stainless steel plates are a viable option. When you need plates that stand up to excessive heat, or difficult atmospheres rings a bell 310S Stainless Steel Plates is the name. Be sure to take the time necessary in your research to find a high-quality vendor who can offer good prices, quick turnarounds and works with you for various customization options.

company's quality management system complete and scientific, accompanied certifications CE certifications, Japanese JIS certificates, EN10219 certifications, EN10210 certifications, EPDs (Environmental Product Declarations) Environmental Product Declarations, French BV Certifications American ABS Classification Society Certifications Norsk Veritas, certificates for system environmental 310S stainless steel plate, ISO9001 certifications, etc.

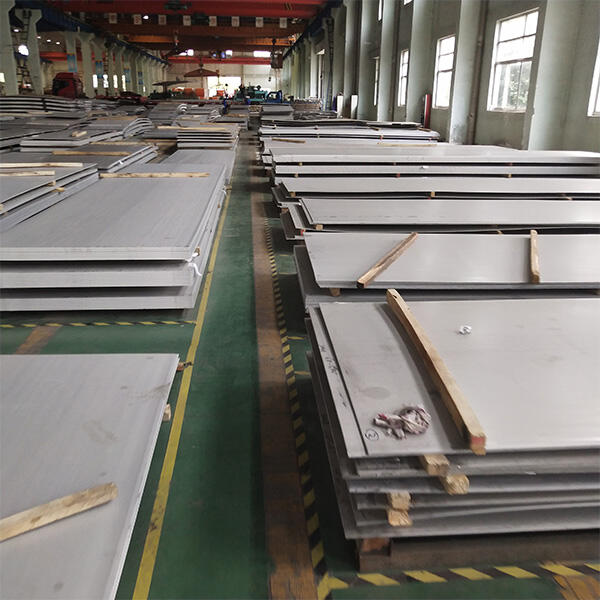

own our own manufacturing line, using raw materials our product keep inventory that 310S stainless steel plate100,000 tons have all sorts of inventory of materials, have their own laser machine, can cut, punch, welding processing.

can also hot-dip galvanizing process, have our hot-dip galvanizing plants that can make products with high zinc layer galvanized, we can spray, sandblast, paint, paint, other 310S stainless steel plate our products. can provide customers with cutting and welding in one stop service, saving customers looking third-party processing, which a result transport costs.

have skilled quality inspection team, each quality inspector has a minimum three years of 310S stainless steel plate and training. production line staffed with minimum six quality inspectors 24/7 to conduct quality tests, make sure that the product's passes 100% and for our products at home and abroad to build solid reputation

Copyright © JingZhan Metal Technology (Wuxi) Co., Ltd. All Rights Reserved Privacy Policy